Establishing a sawdust charcoal production facility presents an opportunity for entrepreneurs to capitalize on a renewable resource while contributing to waste reduction and environmental sustainability. However, like any industrial investment, there are critical considerations to evaluate before moving forward with a sawdust charcoal project. These considerations span from initial capital outlay to operational efficiency, all of which can affect the profitability and long-term success of the venture.

1. Raw Material Supply and Availability

One of the first factors to address when setting up a sawdust charcoal making machine project is the consistent supply of raw material. Sawdust is generated primarily from wood processing industries such as sawmills, furniture manufacturers, and timber suppliers. Identifying reliable suppliers or establishing direct relationships with such industries is crucial to ensure an uninterrupted feedstock for the charcoal production process.

Sourcing costs may fluctuate depending on proximity to the raw material source. It is essential to ensure that sawdust is not only available but also economically viable to collect and transport to the production site. This will help control the overall cost structure and reduce operational risks.

2. Charcoal Machine Price

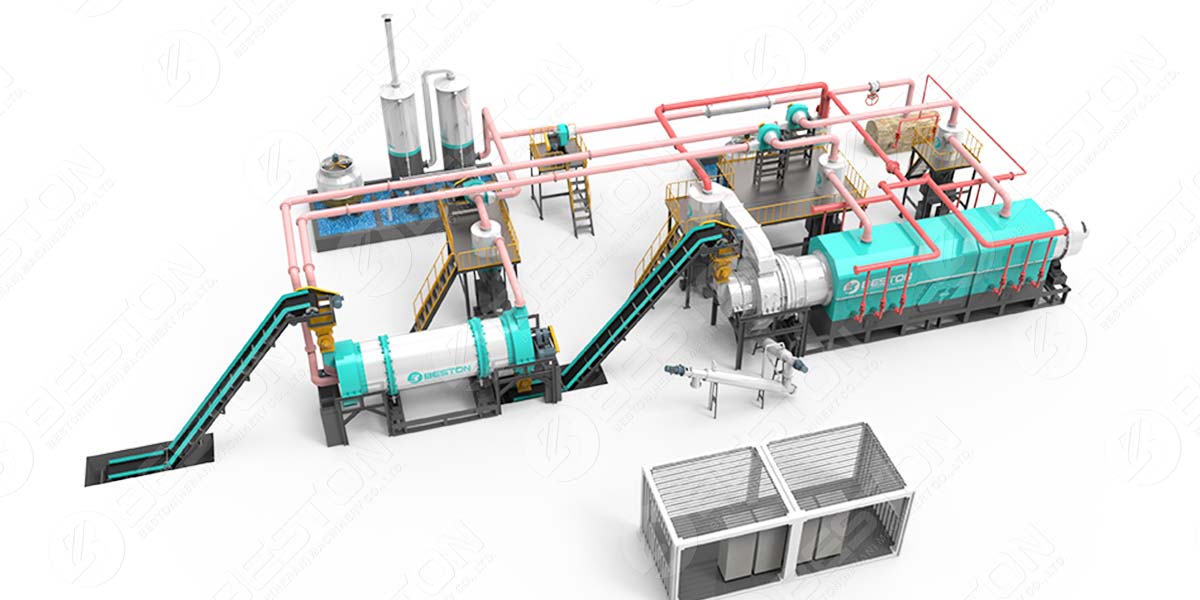

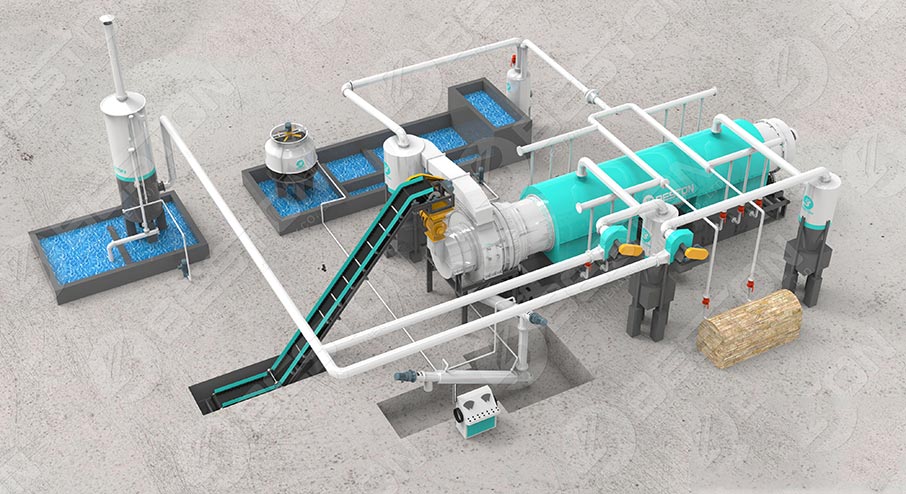

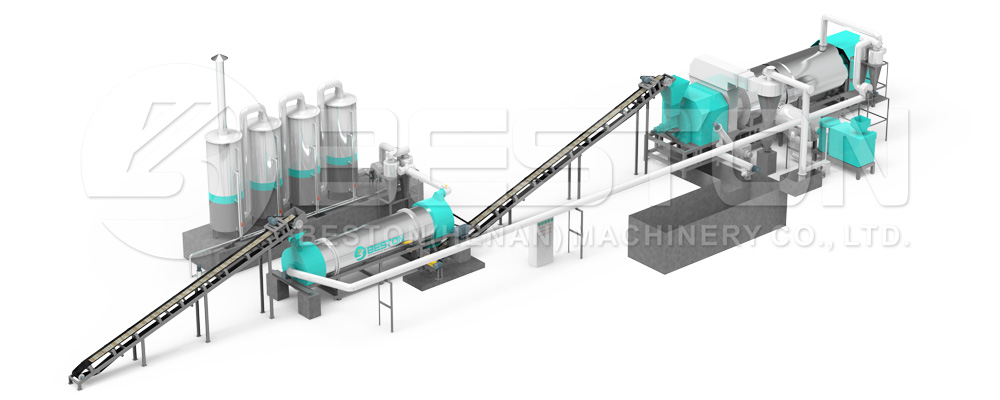

The cost of machinery is another significant consideration. A charcoal machine, which is central to the carbonization process, typically represents a large portion of the initial investment. The charcoal machine price depends on factors such as its capacity, technology, and features.

Advanced machines may feature automated systems, energy-efficient designs, and integrated control mechanisms that enhance productivity and reduce labor costs. These features can translate to long-term savings, although they may increase the initial machine price. It is crucial to compare different manufacturers and models to identify a machine that balances cost and efficiency, ensuring that the investment is both affordable and high-performing.

3. Production Capacity and Scalability

Determining the scale of the operation is critical when establishing a sawdust charcoal project. Small-scale operations may have lower upfront costs, but their profit potential is limited by production capacity. On the other hand, large-scale facilities, while more expensive to set up, may offer economies of scale that reduce unit costs.

When choosing the right production scale, it is essential to forecast both current and future market demand. It is also beneficial to select equipment that is flexible and scalable, such as a charcoal machine that can be upgraded or expanded as demand grows. A well-planned scalability strategy allows for gradual expansion without incurring unnecessary additional costs.

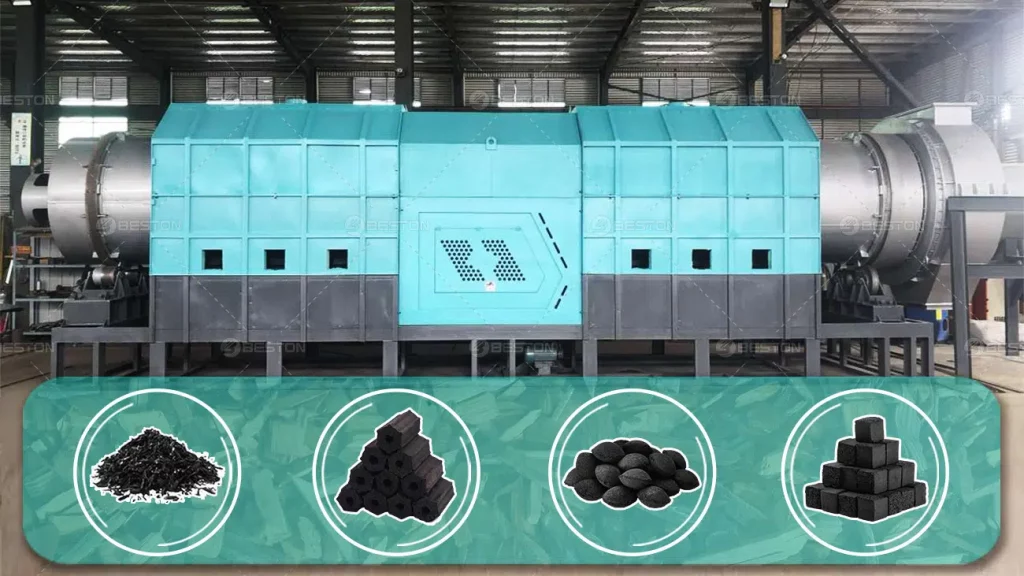

4. Charcoal Briquetting Machine

For businesses seeking to maximize the value of the charcoal produced, incorporating a charcoal briquetting machine into the production line is a key consideration. Briquetting adds value to the final product by compressing the charcoal into uniform, high-density shapes that are easier to handle, transport, and store. These briquettes are often in high demand in both the domestic and international markets, especially in regions with limited access to natural wood fuels.

Investing in a charcoal briquetting machine can improve the overall product portfolio, increasing the attractiveness of the product to a wider range of customers. However, the addition of this equipment increases initial capital expenditure and operational complexity, so careful consideration of the expected returns is needed.

5. Operational and Maintenance Costs

Beyond the initial capital investment, operational and maintenance costs are significant factors in determining the overall profitability of a sawdust charcoal project. Fuel costs for heating the carbonization furnace, electricity consumption, and labor wages all contribute to ongoing expenses. It is essential to budget for these costs while simultaneously exploring energy-saving technologies, such as heat recovery systems, to reduce operational overhead.

Regular maintenance of equipment is also crucial to ensuring longevity and minimizing downtime. This includes maintaining the charcoal machine, briquetting equipment, and other components of the production line. Establishing a clear and realistic maintenance schedule will help prevent costly repairs and ensure consistent production. If you need such assistance, please contact Beston Group China.

6. Regulatory Compliance and Environmental Considerations

The environmental impact of charcoal production is a growing concern, especially regarding emissions and deforestation. Regulatory frameworks may vary by region, but most jurisdictions have guidelines that govern industrial carbonization processes and emissions.

To avoid legal complications and protect the environment, it is critical to ensure that the sawdust charcoal project complies with local environmental regulations. This includes installing emissions control systems, using eco-friendly technologies, and promoting sustainable sourcing of raw materials. Being proactive in environmental compliance not only mitigates legal risks but also enhances the marketability of the product, as consumers increasingly prefer environmentally responsible products.

7. Market Demand and Sales Channels

Before committing to a sawdust charcoal project, market research is essential to assess the demand for the end product. Different markets have varying requirements for charcoal, including specifications for size, shape, and density. Understanding the target market—whether local, regional, or international—will allow for better alignment of production capacities and marketing strategies.

Establishing sales channels and identifying potential customers, such as retail outlets, industrial users, and export markets, will ensure a steady revenue stream. It is also important to consider pricing strategies, based on both production costs and competitive pricing in the market.

Conclusion

Starting a sawdust charcoal production business can be a profitable investment, but it requires a thorough understanding of various factors. From sourcing raw materials to selecting the right machinery and ensuring compliance with environmental standards, every step in the process impacts the project’s success. By carefully considering elements such as charcoal machine price, production capacity, operational costs, and market demand, entrepreneurs can significantly increase their chances of achieving long-term profitability and sustainability in this growing industry.