In the ever-evolving landscape of waste management and sustainable resource utilization, continuous pyrolysis plants have emerged as an innovative solution. These sophisticated facilities have revolutionized the way we harness the potential of organic and non-organic materials through the continuous pyrolysis process. In this comprehensive exploration, we will delve into the intricacies of continuous pyrolysis, its applications, and the cutting-edge technology that drives it forward.

The Essence of Continuous Pyrolysis

Before we dive into the technicalities, it’s crucial to grasp the essence of continuous pyrolysis plant. At its core, pyrolysis is a thermal decomposition process where organic materials are subjected to high temperatures in the absence of oxygen. This controlled environment triggers the breakdown of these materials into valuable byproducts, including pyrolysis oil, gas, and solid char.

Continuous pyrolysis is characterized by its uninterrupted operation, allowing for a steady input and output flow of materials and products. Unlike batch pyrolysis, which operates in discrete cycles, continuous pyrolysis offers greater efficiency and productivity.

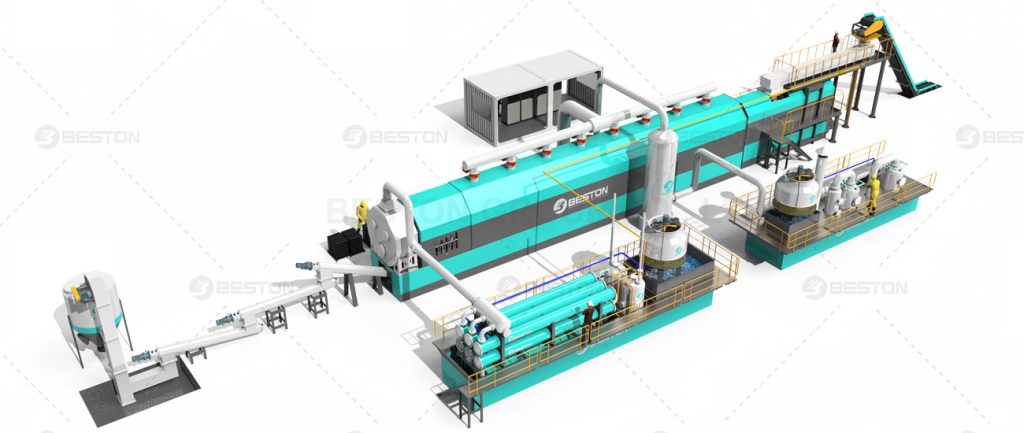

Fully Continuous Tyre Pyrolysis Plant

The Advantages of Continuous Pyrolysis Plants

Continuous pyrolysis plants offer a multitude of advantages that set them apart from their batch counterparts. Let’s explore some of these key benefits:

- Enhanced Efficiency: Continuous operation ensures a constant flow of materials, minimizing downtime and maximizing production efficiency.

- Consistent Quality: The steady processing conditions result in more consistent product quality, especially critical for applications like pyrolysis oil.

- Greater Throughput: Continuous pyrolysis plants are designed for high-capacity processing, making them suitable for large-scale waste management and resource recovery.

- Improved Energy Efficiency: The continuous flow of materials optimizes heat utilization, improving overall energy efficiency.

- Reduced Labor: Continuous plants require less manual intervention, reducing labor costs and the risk of human error.

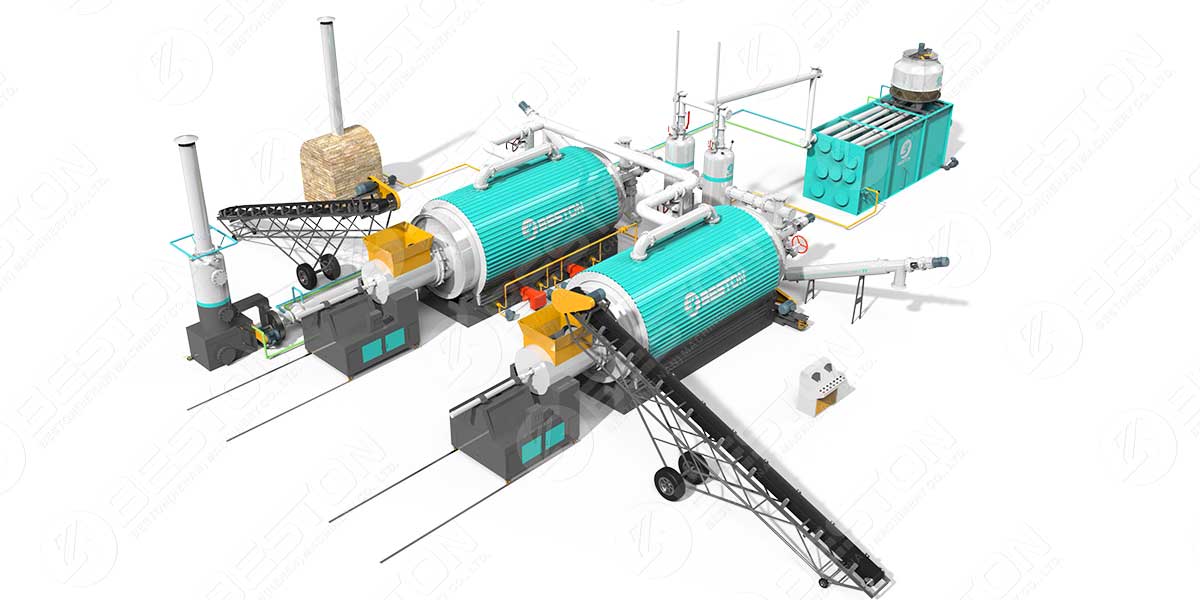

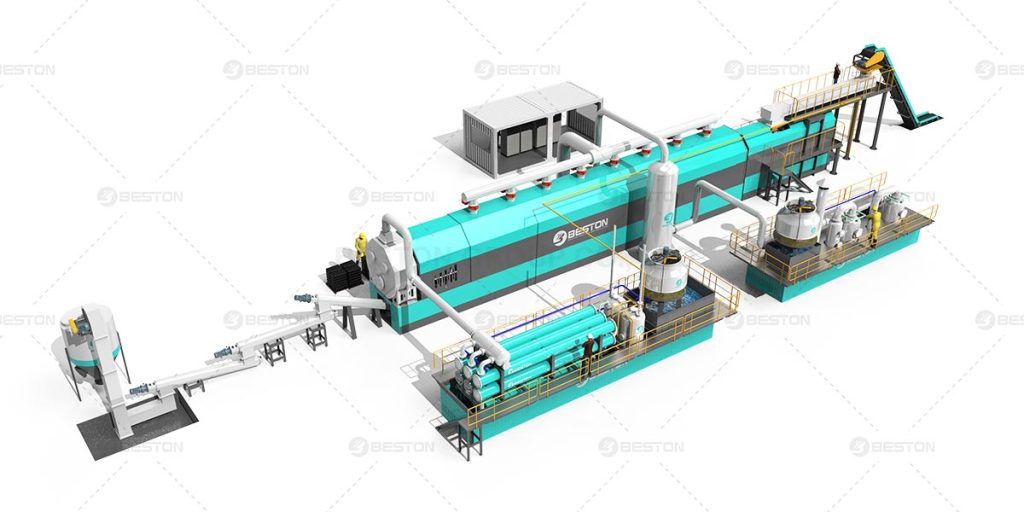

The Core Components of Continuous Pyrolysis Plants

Continuous pyrolysis plants consist of several crucial components that work in harmony to facilitate the continuous conversion process. These include:

- Feeding System: A continuous feeding system ensures a constant supply of feedstock into the reactor.

- Reactor: The heart of the plant, where thermal decomposition takes place. It is often equipped with advanced heating systems and temperature control mechanisms.

- Pyrolysis Gas Cooling and Separation: Gases generated during pyrolysis are cooled and separated to produce valuable products like pyrolysis oil and gas.

- Solid Residue Discharge: The char or solid residue is efficiently removed from the system for further processing or disposal.

- Control and Monitoring Systems: Advanced control and monitoring systems maintain optimal conditions and ensure the safety and efficiency of the process.

Applications of Continuous Pyrolysis

The versatility of continuous pyrolysis plants extends across various industries and waste streams:

- Waste Management: These plants play a crucial role in managing organic waste, plastics, tires, and other non-recyclable materials, reducing the burden on landfills.

- Resource Recovery: Continuous pyrolysis transforms waste materials into valuable resources, including pyrolysis oil, which has applications in fuel production and chemical synthesis.

- Renewable Energy: The gases produced during continuous pyrolysis can be used for energy generation, contributing to renewable energy sources.

- Environmental Remediation: These Beston Group plants are employed in the remediation of contaminated soil and the treatment of hazardous waste.

- Metallurgy: Continuous pyrolysis is utilized in metallurgical processes as a source of reducing agents in metal production.

Installation of Continuous Tyre Pyrolysis Plant

Technological Advancements in Continuous Pyrolysis

Continuous pyrolysis plants have witnessed significant technological advancements in recent years:

- Advanced Reactor Design: Innovations in reactor design optimize heat transfer and residence time, improving overall efficiency.

- Catalytic Pyrolysis: The integration of catalysts enhances the pyrolysis process, resulting in higher yields and better product quality.

- Automation and Control: State-of-the-art automation systems and real-time monitoring enable precise control of operating conditions.

- Heat Recovery: Advanced heat recovery systems capture and reuse heat generated during pyrolysis, reducing energy consumption.

- Feedstock Flexibility: Continuous pyrolysis plants are designed to handle a wide range of feedstock types, from plastics to biomass.

Environmental and Economic Implications

The adoption of continuous pyrolysis plants holds significant environmental and economic implications:

- Waste Reduction: These plants divert substantial amounts of waste from landfills, mitigating environmental impact.

- Resource Efficiency: Continuous pyrolysis maximizes resource recovery, contributing to a circular economy.

- Reduced Carbon Footprint: The use of pyrolysis oil as a fuel source can reduce greenhouse gas emissions, promoting environmental sustainability.

- Energy Independence: By generating renewable energy from waste, countries can reduce their dependence on fossil fuels.

- Job Creation: The growth of continuous pyrolysis plants creates employment opportunities in waste management and resource recovery sectors.

The Future of Continuous Pyrolysis

As we look to a future with ever-increasing waste challenges and the imperative to transition towards sustainable practices, continuous pyrolysis plants are poised to play a pivotal role. Their technological sophistication, efficiency, and versatility position them as a cornerstone in the journey toward a greener and more resource-efficient world. The relentless pursuit of innovation in this field promises not only effective waste management but also the harnessing of valuable resources from what was once considered waste, reshaping our approach to sustainability and resource utilization. Get pyrolysis machine price here.