If you are planning to set up your own waste tire to oil plant, there are a few things that should be a part of your business plan. These waste tire to oil plants or pyrolysis plants have gained a lot of popularity. Recycling waste tires is a big business everywhere as mounds of waste tires are piling up in landfills and local governments want to get rid of those mountains of waste tires at any cost.

Pyrolysis technology offers a profitable way to recycle this waste and that is why, it is an excellent business opportunity for someone like you. However, many beginners in this industry are surprised to learn that a good number of pyrolysis businesses end up in losses within the first five years. Like any other business, you need to have a business plan to ensure the survival and profitability of the business in the long run.

This is why you need to focus on building a tyre to oil plant that incorporates all the potential costs and expected challenges. Here are a few things that should be an essential part of a successful business plan for a pyrolysis plant:

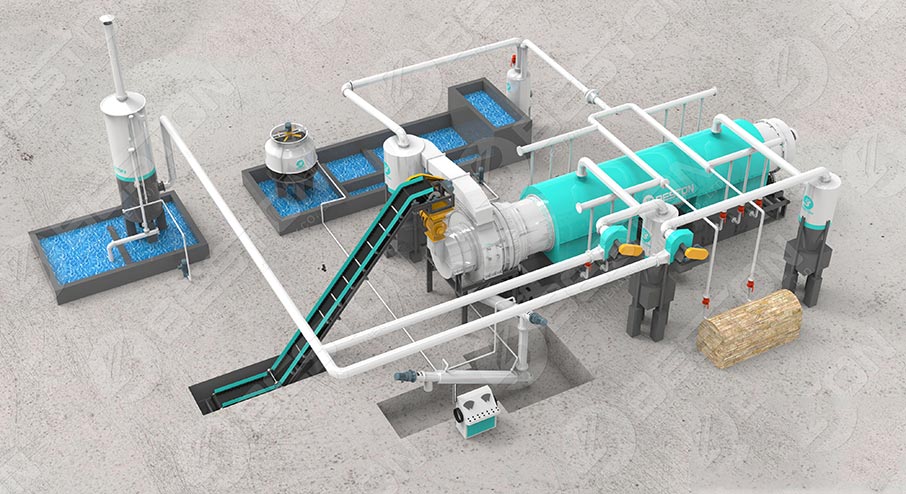

Tire to Oil Plant

Type of Plant

One of the first things you need to finalize is the type of plant you’re going to use for your business. These are available in continuous processing and batch type configurations. Choose a configuration based on your specific requirements. Keep in mind that you will also need to invest in pre-processing of tires. If you do not have a facility nearby for pre-processing of tires, you might want to consider investing in your own pyrolysis machine for sale. Tires need to be cut into chunks of approximately 2 inches to ensure maximum yield.

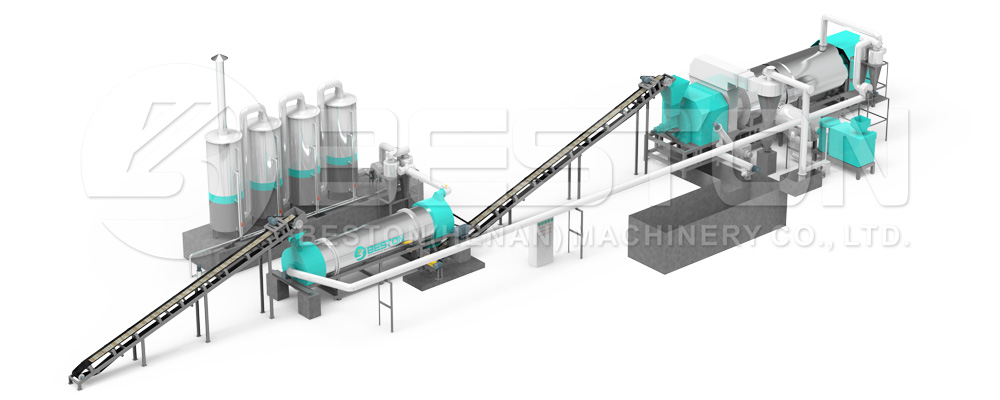

Fuel Efficiency and Yield

Needless to say, you would want to buy a plan that offers maximum yield and fuel efficiency. When it comes to maximizing efficiency and yield, you can’t rely on the theoretical results provided by the manufacturers on their websites. You need to get real world results.

Talk to people who are already operating plants you’re considering. It will help you get a good idea of the real-world yield and fuel efficiency you can expect. You also need to find out the types of fuel that can be used in the plant you’re planning to buy. Some plants have good flexibility and allow you to use a wide range of fuels. On the other hand, some plants are limited to use of only a particular type of fuel. It is better to choose a plant that offers flexibility in terms of type of fuel that can be used. Get pyrolysis plant cost here.

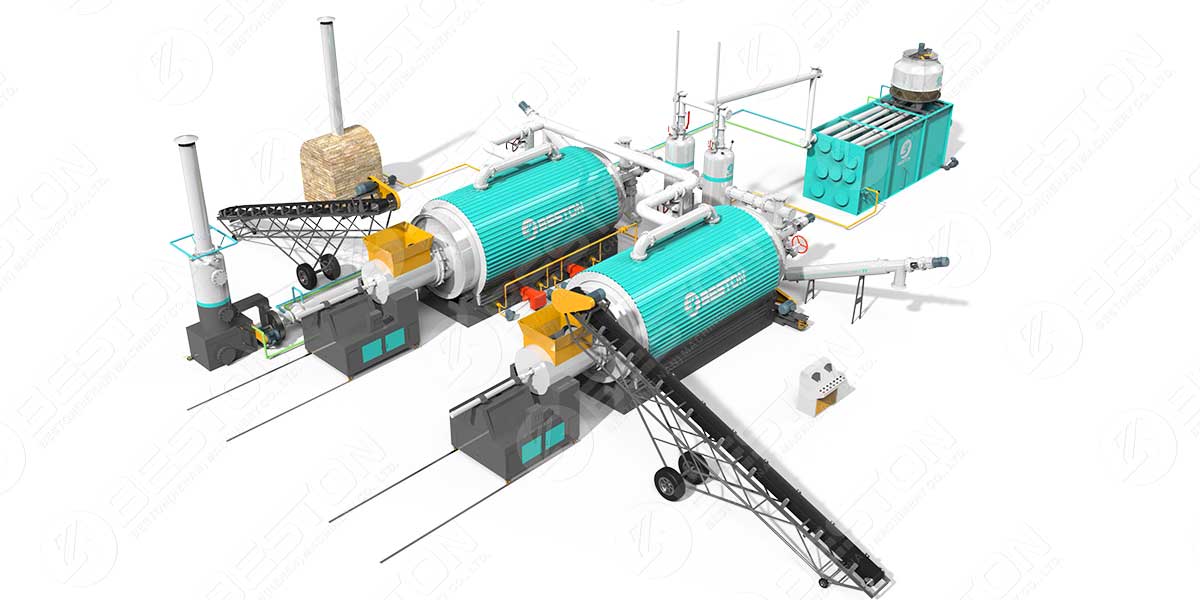

Cost of the Plant

When the initial cost of the plant is important, that shouldn’t be your only focus. Don’t forget that it is a technology business. Better technology usually means better chances of survival in the industry as competitors will always be investing in better technology. This is why you should always try to buy a plant with maximum efficiency and yield even if it is a bit expensive as compared to alternatives.

Conclusion

Overall, a wide range of pyrolysis plants are available in the market for sale. It is important that you should focus on fuel efficiency, yield as well as technology and not just on the initial price to ensure long-term success in this business. More information on the thermal desorption unit here.