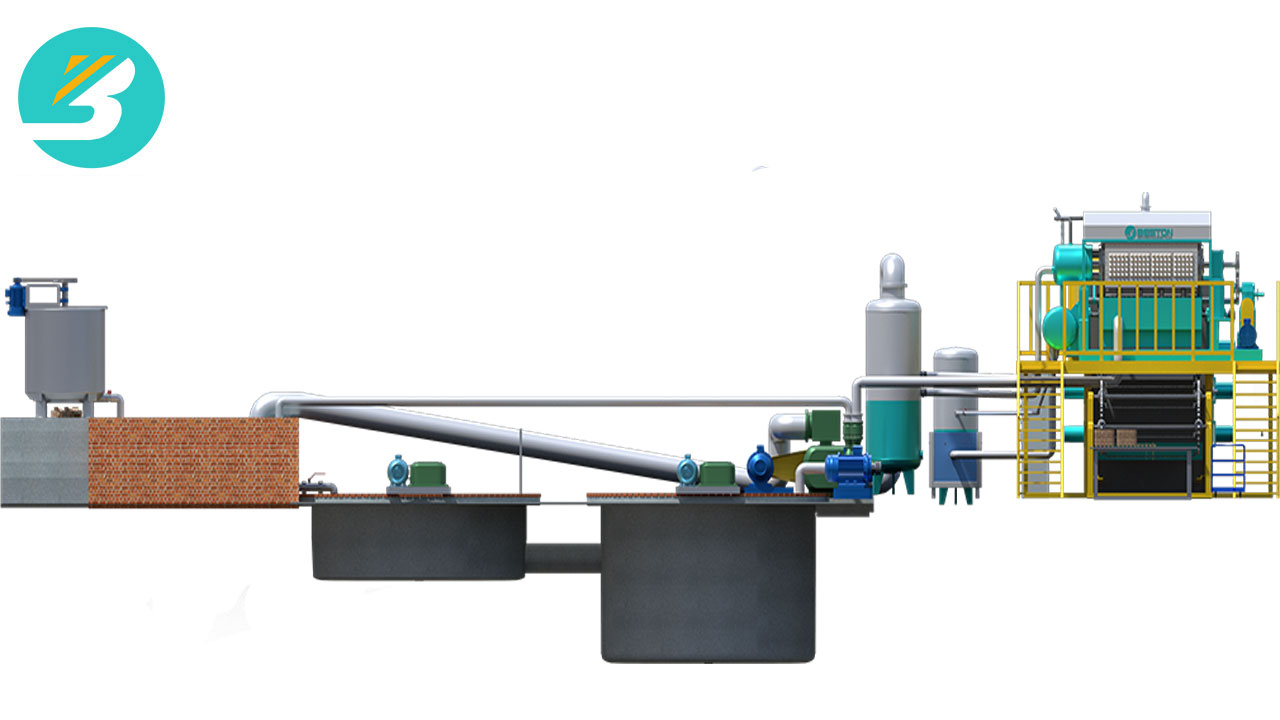

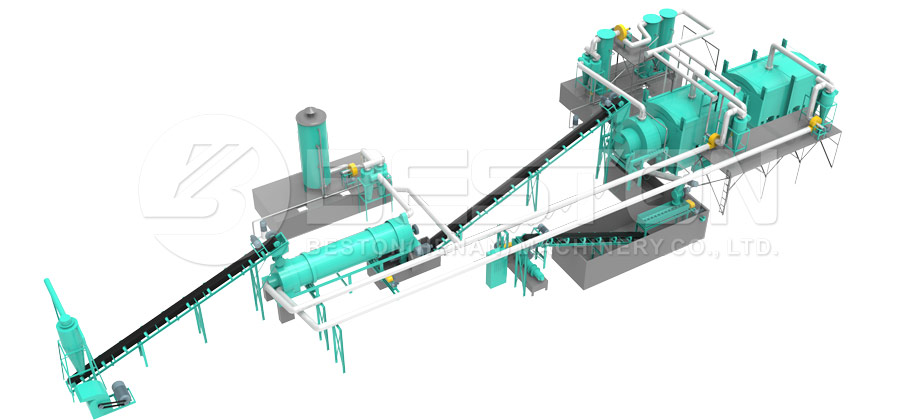

The charcoal making machine has become a popular piece of equipment in many countries throughout the world. This machine allows you to convert biomass waste, including wood, sawdust, rice husks, coconut shells, palm kernel shells, as well as sewage sludge into charcoal and other useful byproducts. This process is achieved by heating the biomass waste in an oxygen-free environment, a process known as carbonization. The charcoal making machines and their end product and by-products have a wide range of applications, opening up many opportunities for entrepreneurs.

For instance, the charcoal produced can be used as a fuel in many aspects of daily life including BBQ charcoal, and fuel for boilers and warmers. In agriculture, it is attached to heavy materials to enhance the quality of the soil. In industries, it is often used as a fuel for manufacturing factories, reprocessed into activated carbon, and used to make construction bricks with clay. Biogas, a by-product of the charcoal making machine is widely used as fuel in homes and industries, and it is also used for greenhouse agricultural heating. Tar, another by-product, plays a crucial role in the smelting of bio-diesel. Wood vinegar is widely used in the agricultural industry in making pesticides and fungicides.

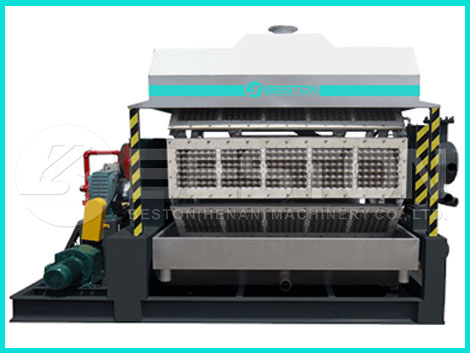

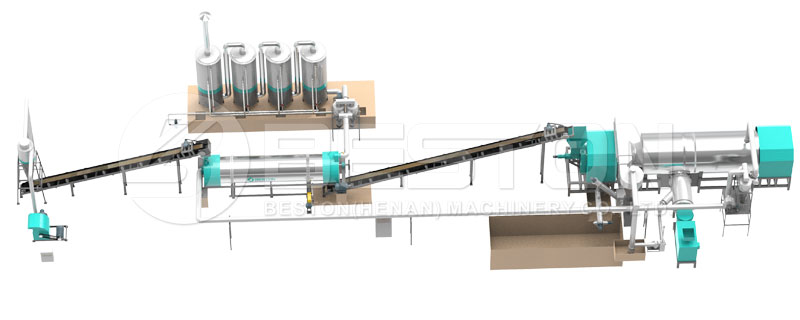

Beston Charcoal Making Machine for Sale

As you can see, the palm kernel shell charcoal machine is a highly useful piece of machinery. Besides offering a perfect solution to your biomass waste problem, it helps to create many business opportunities for entrepreneurs. If you are looking to start a business, here are some of the reasons you should consider investing in a charcoal making machine:

A wide range of raw materials

The charcoal making machine utilizes all kinds of waste plant materials to make biochar. From wood, sawdust, bamboo, rice husks, coconut shells, palm shells and many others. These raw materials are cheap and easy to find, especially in countries with tropical rainforest climates. The abundance and ease of access to these materials means that you are able to minimize your direct material costs increase your profit margin.

Quick Return on Investment

A charcoal-making machine is by no means a cheap piece of rice husk carbonizer. However, one of its best perks is that it offers a quick and high return on investment. You should be able to recoup your initial investment within a short period of time, especially if you choose to sell the products you make. There is currently a high demand for charcoal, both for domestic and industrial purposes. By filling this gap, you will be able to enjoy high profits and grow your business.

Helps to Solve the Agricultural Waste Disposal Problem

The charcoal-making machine allows you to turn agricultural waste into a high-quality product that has many uses and can be sold for a profit. If you live in an agricultural area or engage in intense agricultural activities, you are likely dealing with a quick buildup of agricultural waste and spending a lot of money to dispose of it. The charcoal-making machine offers the perfect waste disposal solution.

Batch Charcoal Making Machie Delivered to Ghana

Get More Charcoal for Less

If you are used to sourcing your charcoal from a supplier, you are aware how expensive it can get. Fortunately, with a charcoal making machine, you are able to make high quantities of high-quality biomass charcoal at a cheap cost. This not only helps you to earn great savings but it also offers you the opportunity to earn an extra income. Get some good options on this company – China Beston Group.