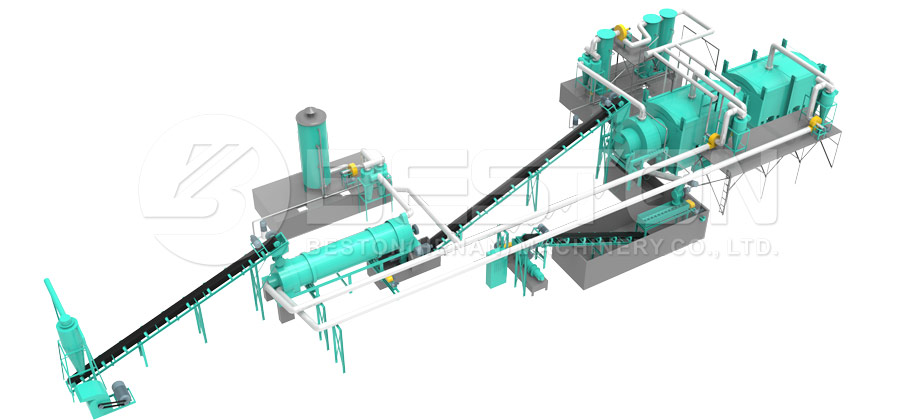

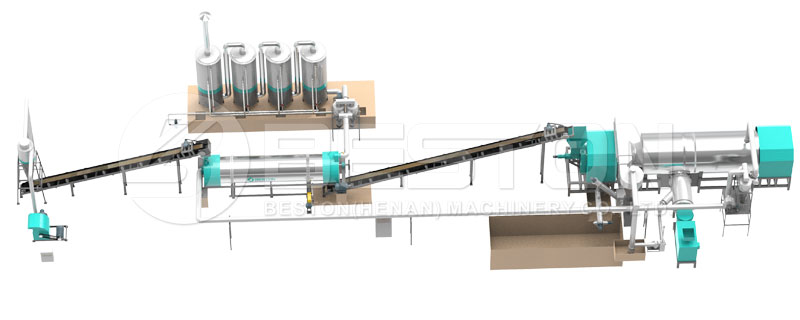

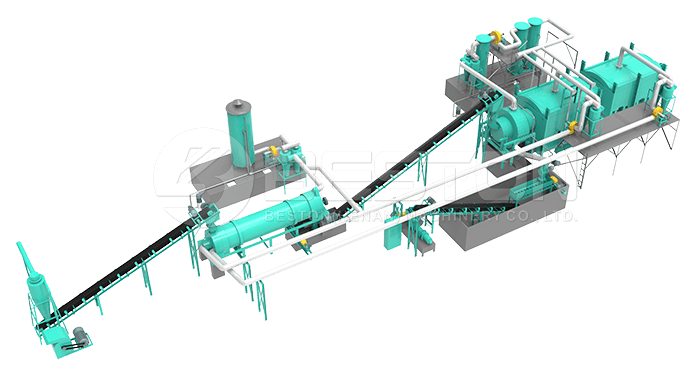

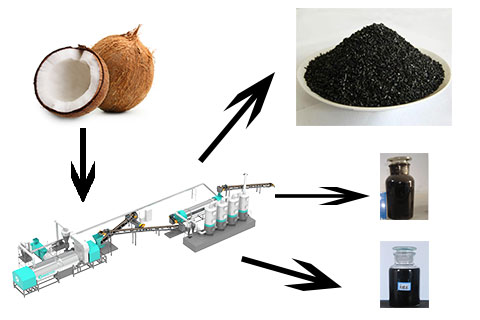

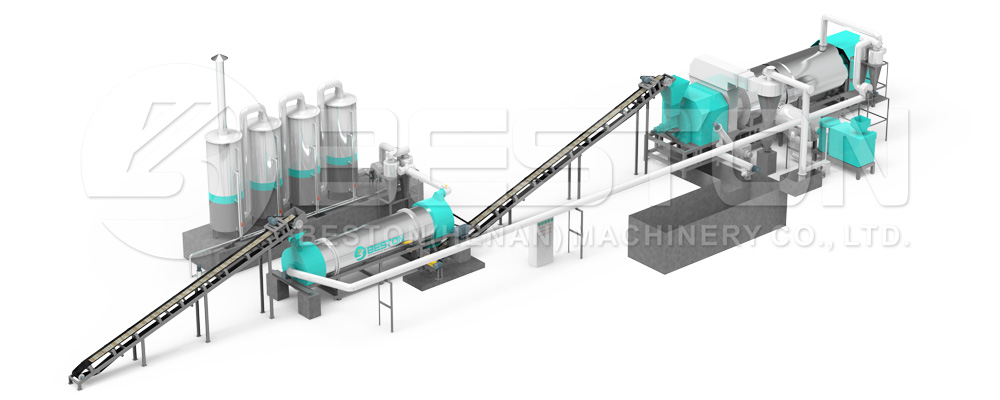

Also referred to as charcoal, biochar is a natural byproduct of the pyrolysis process. When organic material is converted, through extreme heat into charcoal, this is done by using biochar production equipment. This can come in various sizes. You can invest in an entire plant if you want to. Overall, it’s a great way to utilize materials that you may be disposing of every year. Instead, you will be able to convert this into burnable fuel that you can use and sell. If you want the very best biochar equipment to produce charcoal and bio oil, here is how you can find the best biochar machine.

Biochar Production Equipment

Biochar Machines Or Plants?

There is often a debate as to what size of pyrolysis plant you should invest in. For example, biochar machines are very popular with small to medium size companies. This determination can also be made by looking at how much access you have to materials that you can use. If you have a substantial amount of material, it’s a good idea to invest in a charcoal maker machine which can handle an excessive amount of volume.

Where To Obtain Pyrolysis Plants And Machines

The businesses that you locate on the web may not necessarily be close by. You may have to order these machines from a company thousands of miles away. What you need to assess is the viability of the company, is reputation, and the quality of the machines that they are producing. In the same way, if you are investing in a coconut charcoal making machine, you must consider there output, size, and how much it will cost to operate them. You can obtain these from countries like China that are known for producing some of the best units in the world. Additionally, countries such as India, and even the Philippines, are great sources for these industrial machines.

Biochar Machine To Ghana

Is It Beneficial To Own One?

If you do have a large amount of this material available, you should consider getting an extremely large and robust pyrolysis plant. If you can produce tons of this material, it’s going to be very easy to recoup the investment that you are making into one. On the other hand, if you have a small amount of biodegradable material, or even plastic and rubber, you can convert all of this into charcoal and biofuel. It would be very advantageous to own one if you do have access to these machines that can produce charcoal.

Fully automated biochar production equipment is relatively easy to find. You may not realize how many businesses in the world are producing them on an annual basis. The size of the machines, and where they are located, will help factor into your final choice. Always remember the cost of shipping and other fees that you will have to pay, to have it delivered to your facility. Once fully operational, you can utilize all of these disposable materials, creating all of the charcoal and bio-oil that you will need. It’s a great way to preserve the environment, and at the same time, profit from your efforts as you convert this material to burnable fuel on a daily basis. Overall, these machines are simply popular because they can help your business recycle materials and also make a profit. More information on wood to charcoal machine here.