Waste tyres are a great resource for extra revenue in the industrial sector. Many companies have made investments in recycling plants and machines which turn tyres into great sources of revenue. If you’re currently looking to expand into new operations, then you should definitely look into the possibility of acquiring recycling plants for waste tyres. With this in mind, here are some crucial aspects to keep in mind regarding high-quality waste tyre recycling machines. More information about tyre recycling plant cost here.

Waste Tire Recycling Plant

Client testimonials are fantastic for providing you with the right perspective regarding the various manufacturers in the industry. Testimonials written by trusted companies and managers within the sector should give you an objective idea about which brands would be most suited to your business. Look into the details of each testimonial, such as the quality of customer service as well as costs of maintenance. From there, you should have a reasonably clear idea about which specific manufacturing firms you might want to consider when making a decision regarding an acquisition.

Cost analysis is key when analyzing prospective waste tyre recycling machines for acquisition. You must find a tyre pyrolysis plant that has low long-term costs. Machines which have low long-term costs are bound to provide you and your company the best return possible. Make sure to avoid gimmicky machines with highly technical features. These machines often are very costly in the long-term due to things like high power consumption. Thus, a key trait for many of the best performing recycling machines in the market is those with the lowest long-term costs.

Ultimately, one of the best traits to look for when choosing waste tyre recycling machines is the brand reputation of the manufacturer. Certain manufacturers have spent decades creating recycling machines at the highest standards within the industry. These manufacturers have cultivated a loyal following of clients that understand that their products are the best of the best. Although these brands often charge a premium for their pyrolysis oil plant, the reliability and effectiveness of their products are almost guaranteed. Thus, going with the most recognized and reputable brands is the best option if you’re looking to play it safe.

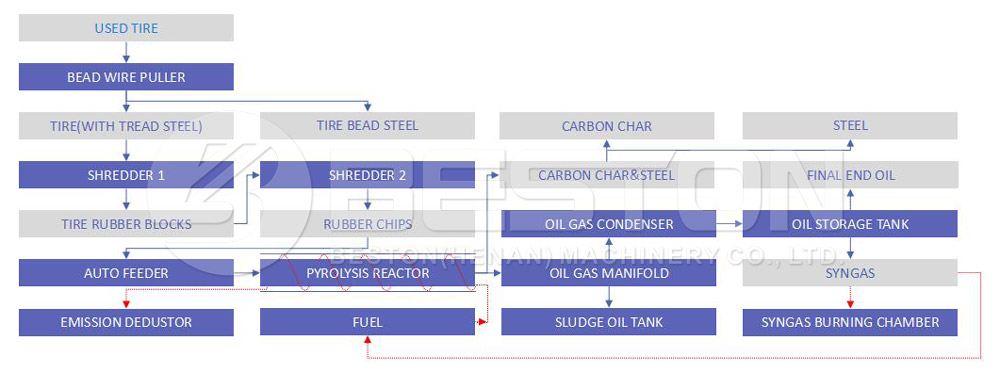

Waste Tire Recycling Process

At the end of the day, it’s up to you and your stakeholders to decide which waste tyre recycling machine is best for your business goals. Certain machines are better suited to conservative companies looking for a reliable income stream. Companies that wish to take a bit of a bigger risk should look towards some of the newest machines recently released, as they have the highest potential for great returns. More information on pyrolysis machine cost here.