Charcoal making machines are versatile equipment used in converting various raw materials into charcoal, a valuable resource for numerous industries. These machines have different names based on the specific processes they perform or the types of materials they handle. Let’s explore several common names of charcoal making machine.

Charcoal Making Machine

The term charcoal making machine broadly refers to any equipment used for transforming organic materials into charcoal through carbonization. These machines are equipped to handle a variety of raw materials, such as wood, sawdust, rice husks, and other biomass. A charcoal making machine typically involves a process where the material is heated in the absence of oxygen, allowing it to decompose into solid carbon, or charcoal. This equipment is popular in both small-scale and large-scale production, and it is known for its efficiency, reliability, and environmentally friendly operation.

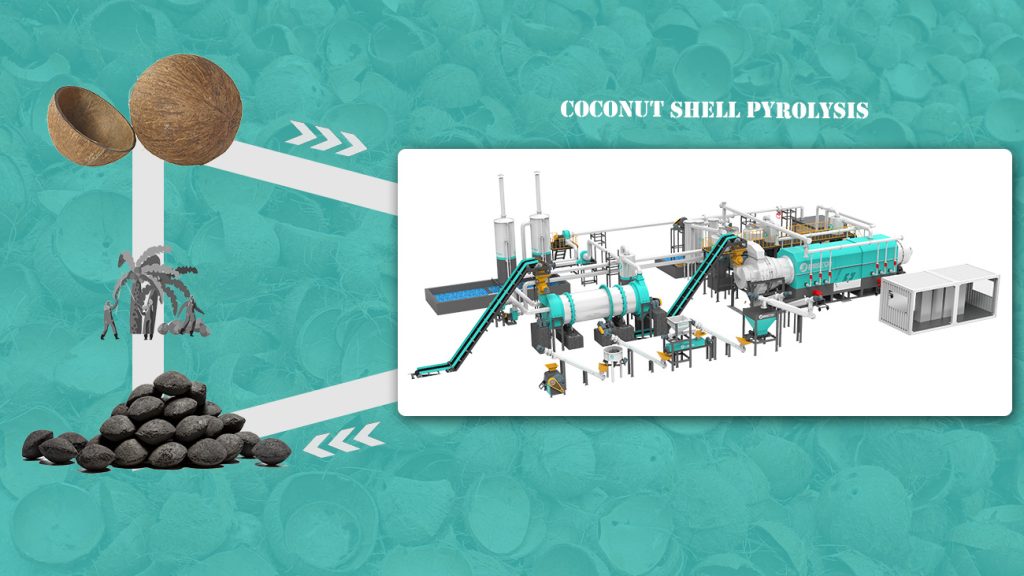

Coconut Charcoal Machine

It also often adds a prefix to “charcoal machine” depending on the raw material being processed, such as coconut charcoal machine, wood charcoal machine, bamboo charcoal machine, and more. For example, a coconut charcoal machine is a specialized type of charcoal making machine designed specifically to convert coconut shells into high-quality charcoal. Coconut shells are a common biomass material rich in carbon, making them ideal for producing charcoal. The coconut charcoal machine is particularly popular in tropical countries where coconuts are abundant. These machines are designed to handle the unique properties of coconut shells, providing a stable and efficient carbonization process. The charcoal produced by a coconut charcoal machine is often used in shisha and barbecue applications due to its high heat output and minimal smoke production.

Biochar Pyrolysis Reactor

A biochar pyrolysis reactor is another type of charcoal making machine that focuses on converting organic waste into biochar, a form of charcoal used for soil enhancement. This reactor operates under high temperatures in the absence of oxygen, enabling the thermal decomposition of biomass into biochar, syngas, and bio-oil. The primary function of the biochar pyrolysis reactor is to produce biochar that improves soil fertility, retains moisture, and sequesters carbon, thus contributing to sustainable agriculture and environmental conservation. Many biochar pyrolysis reactors are designed with advanced features that allow for continuous operation, enhancing productivity and energy efficiency.

Biomass Carbonization Machine

The biomass carbonization machine is a general term for equipment used to convert different types of biomass, such as agricultural waste, wood chips, and bamboo, into charcoal. Like the charcoal making machine, it involves a carbonization process but is tailored specifically for biomass materials. The biomass carbonization machine is valued for its versatility in handling a wide range of feedstocks and its ability to produce a consistent quality of charcoal. This machine is commonly used in industries that focus on sustainable practices, as it helps to recycle organic waste into valuable products while reducing carbon emissions.

Conclusion

Understanding the different names and types of charcoal making machines helps in selecting the right equipment for specific needs. Whether it is a general charcoal making machine, a specialized coconut charcoal machine, a dedicated biochar pyrolysis reactor, or a versatile biomass carbonization machine, each plays a vital role in the production of charcoal from various materials. Each name reflects a unique functionality or focus, but all share the common goal of converting waste into valuable charcoal while promoting sustainable practices.