It is difficult to select a reliable egg crate making machine since there are so many different options on the market. If you can find a reliable egg crate making machine from Beston, you can run your business smoothly. Therefore, you need to compare the different machines on the market and their prices before selecting one.

Here is how to select a reliable egg crate making machine for sale:

Manufacturing Capacity

You need to check the production level of the machine before choosing one. You will use the machine to produce egg crates. So, you must know the number of crates you want to produce. Once you know the number, you can now look for an egg crate making machine that can comfortably produce that number.

Choose A Reliable Vendor

Choosing a reliable vendor can help you get reliable egg box machine suppliers. It is, therefore, essential to check the reputation of the vendor. If the vendor is trustworthy, you can purchase their machines. You do not, however, have to rely on local vendors. Reliable international vendors can get you affordable, reliable machines.

Mode of Operation

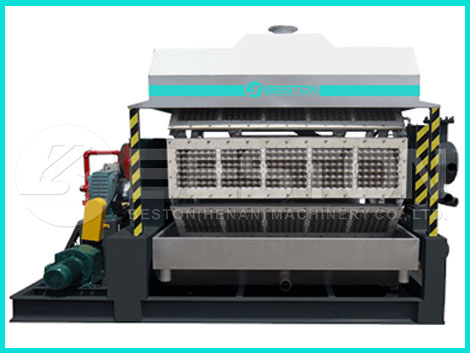

There are manual, semi-automatic, and automatic egg crate making machines. You need to know the benefits of the different modes of operation. It is much easier to use semi-automatic and automatic egg crate machines. However, it is much cheaper to purchase and use manual egg crate making machines.

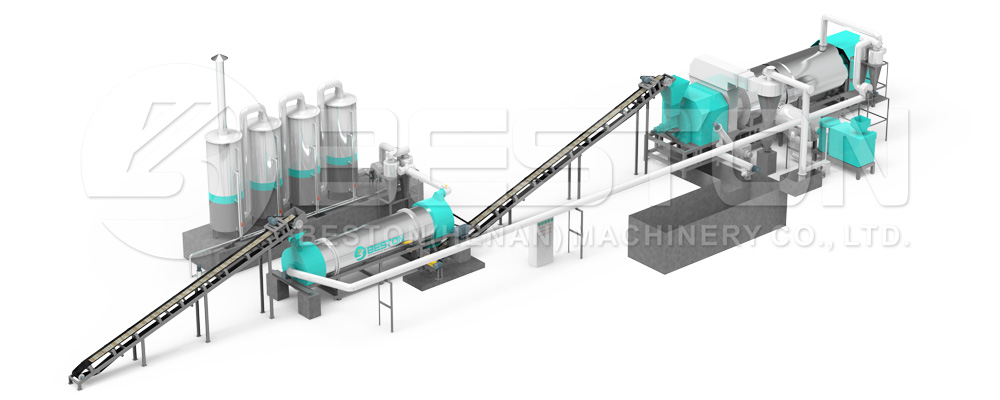

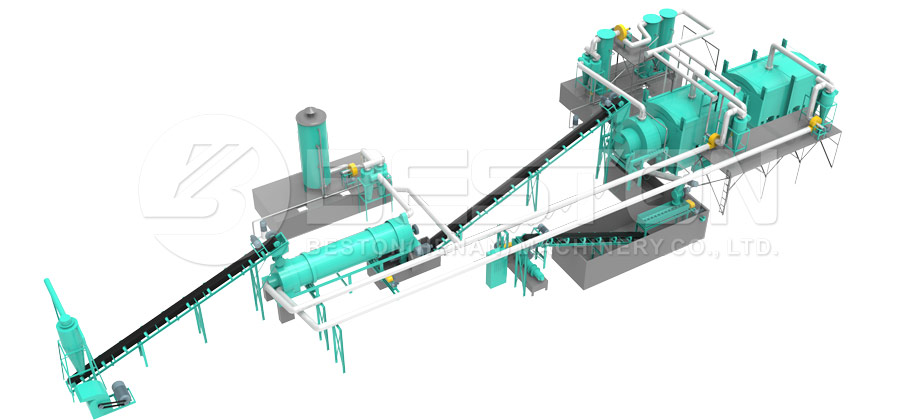

Efficient Egg Crate Making Machine for Sale

Purchase A Machine That’s Under Warranty

If you want to avoid getting scammed, you need to purchase an egg crate making machine that is under warranty. In fact, you can ask to check the warranty before purchasing the machine. In addition, you need to know the coverage the warranty provides. If the warranty provides a higher level of coverage, select that machine.

Egg Crate Making Machine Cost

If you are willing to spend more money, you are more likely to get a reliable egg crate making machine. However, if you are select the cheapest egg crate making machine, you can get disappointed with the machine. It is better to spend more on a durable machine. It is best to strike a balance between value and cost. Please visit Beston website for more details: https://bestonasia.com/egg-carton-machine-for-sale/.

Choose Popular and Trustworthy Brands

Popular and trustworthy egg crate making machine manufacturers make reliable machines. In fact, they have a reputation for excellence. If the brand is reliable, you can rest assured their machines are reliable. It is even easier to deal with these brands after you purchase their machines.

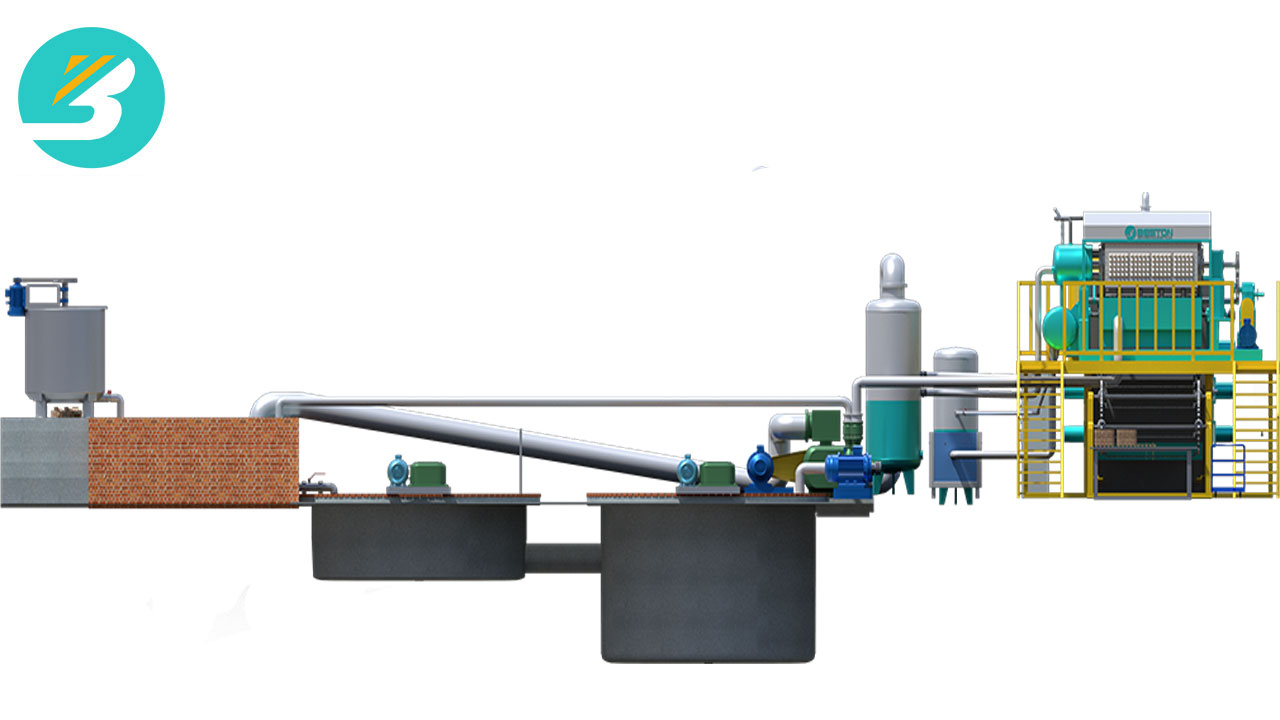

High Quality Egg Crate Making Machine from Beston

Referrals

It can take time to find a reliable egg crate making machine for sale on your own. Get recommendations from experts to save you time. In fact, if you have been in this industry for some time, you may know several people in this industry. You can, therefore, ask these people to recommend a reliable egg create making machine.

Conclusion

Purchasing a reliable egg crate making machine from Beston Group China can save you time. But it takes time to find a good machine. It is crucial to do proper research to avoid losing money. If you can find a trustworthy brand, you can purchase their machine.