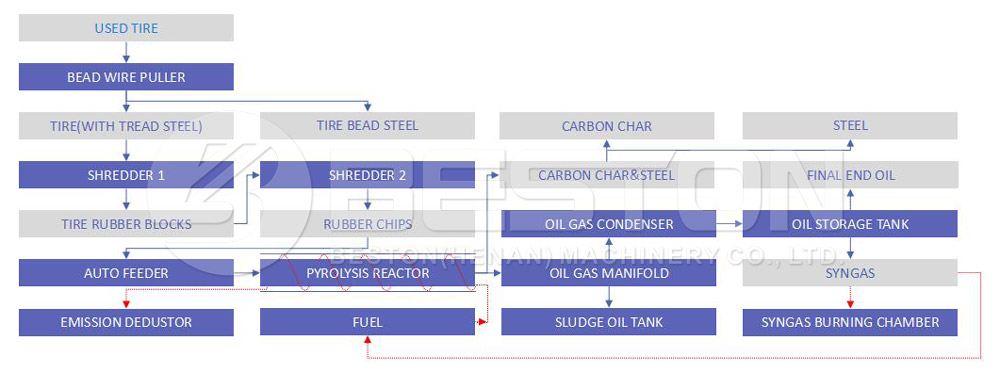

A fully continuous pyrolysis plant is an ideal piece of machinery for recycling different types of waste, such as plastics, oil sludge, municipal solid waste, rubber, scrap tires, agricultural waste, etc. Such a plant is particularly well-suited for the recycling of scrap road tires, which can cause large amounts of damage to the environment when they are disposed of inappropriately.

Continuous Tyre Pyrolysis Plant to Romania

A Beston continuous waste tire pyrolysis plant is easy to install and has fast delivery and multiple service guarantees from the manufacturer. As a result, the model is viewed as the go-to option for investors in the industry. With that in mind, in this blog post, we are going to talk about some of the features of Beston’s pyrolysis plants.

Semi-Continuous Vs Continuous

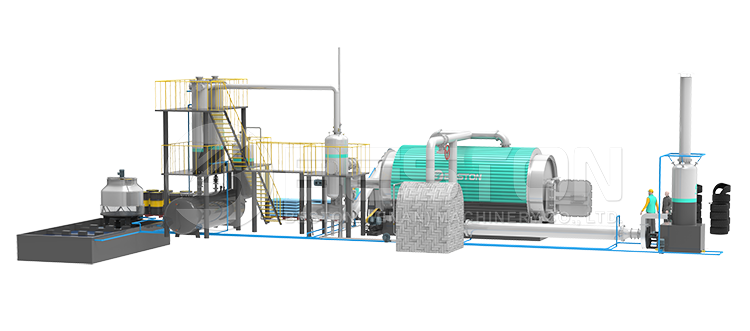

First, it’s important to understand the difference between batch, semi-continuous pyrolysis plant, and their fully continuous plant. The batch and semi-continuous plants have rotary reactors and screws automatic feeders. The screw automatic feeders are needed to transport tire waste into the main reactor without letting too much air (oxygen) into the system. The machines are easy to operate and don’t require a large manual laborforce.

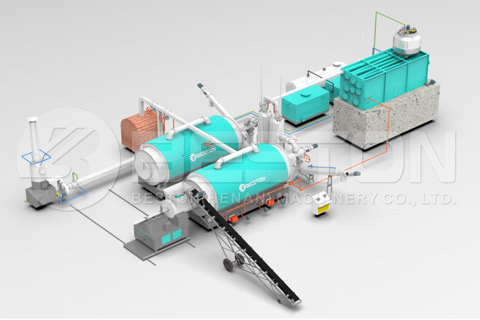

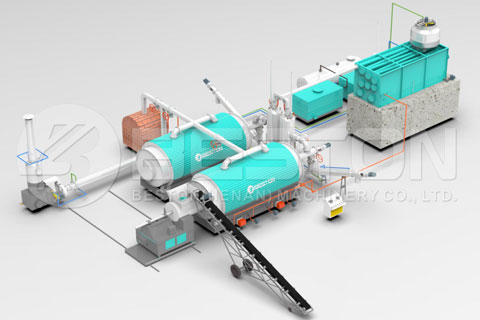

Unlike semi-continuous models, continuous tyre pyrolysis plant, such as the BLL-20, have horizontal reactors and screw automatic dischargers. The machines offer a high level of automation and can utilize the combustible gas produced more efficiently. By investing in such a plant, businesses can save money on fuel costs, manual labor costs, maintenance costs and more. Also, because plant operations are monitored by computers and multiple sensors, the safety ratings of fully continuous tire pyrolysis plants are very good.

Continuous Pyrolysis Reactor

Businesses that are looking to convert a massive amount of raw materials into pyrolysis oil in the fastest time, should opt for the continuous tire to oil machines over semi-continuous and batch options. To automate all areas of the production line in a tire recycling factory, businesses can invest in an automatic tire shredder. Such a shredder ensures that all of the tires are ground into evenly sized small pieces, ready for efficient pyrolyzation in the reactor.

Note: As semi-continuous and continuous pyrolysis plants have different reactor configurations, fuel requirements are also different. You should contact the manufacturer to find out about compatible fuel sources for the different types.

Zero Pollution

The good thing about Beston’s waste tire pyrolysis plant is that they have a 4-stage emissions cleaning system to pre vent any pollution being emitted. During the first stage, smoke is cooled using recycled water cooling condensers. Next, the smoke is cleaned using water spraying, ceramic ring adsorption technology and water washing. Finally, to ensure the plant emissions meet EU emission standard requirements, the smoke is sent through an activated carbon adsorption tower. The advanced dedusting systems in modern tire to oil plant are now so effective that zero pollution is output from a waste tire pyrolysis plant.

If you visit Beston’s website, you will find in-depth details about many successful projects involving waste tire pyrolysis plant installations from international customers. You can also signup for a free price quote for the latest automatic tire to oil machines. Here is a website for you: https://mswrecyclingplant.com/waste-tyre-pyrolysis-oil-plant/.