Continuous tyre pyrolysis plants are important for processing waste rubber tyres into carbon black and fuel oil for recycling use. Investing in a continuous pyrolysis plant is a big decision that involves a lot of money. Hence, you need to be cautious of what type of machine you plan to invest in, and how you plan to use it to recycle waste rubber tyres. This article provides information on what you need to know about a continuous tyre pyrolysis plant, and how to choose the right machine for your business.

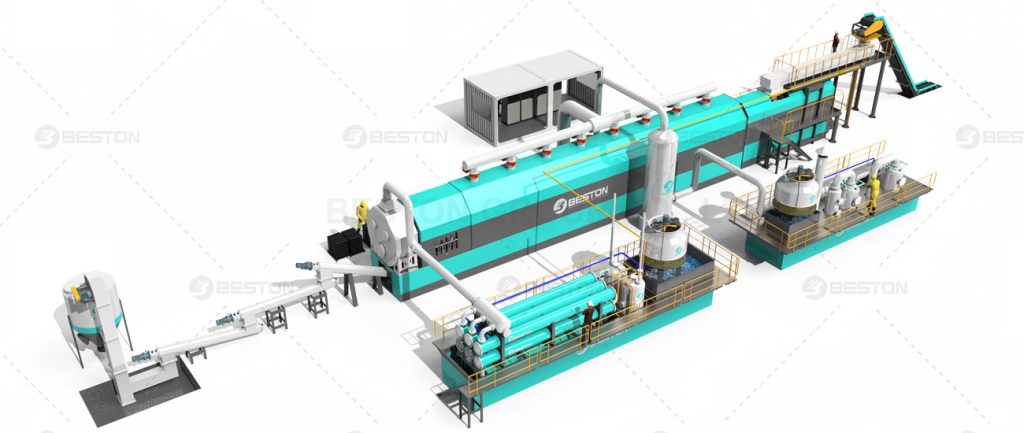

The Main Components Of A Tyre Pyrolysis Plant Machine

The continuous tyre pyrolysis plant consists of 13 parts such as:

- The reactor

- Transmission device

- Cooling tube

- Catalytic Chamber

- Water-oil separator

- Heavy tank

- Light oil tank

- Condenser

- Vacuum system

- Safety device

- Chimney

- Draft fan

- Dedusting system

The reactor and condenser are the two most important components of the pyrolysis plant.

Beston Fully Continuous Pyrolysis Plant

Raw Materials

When you invest in a continuous tyre pyrolysis plant, you should have a way of finding applicable raw materials. The applicable raw materials for a pyrolysis reactor are any kind of waste tyres and plastic waste. For example, you can use bicycle tyres, motorcycle tyres, truck tyres, car tyres, inner tubes, waste rubber, and waste plastic products. Different raw materials will have different oil yields. In fact, the oil yield of waste rubber and waste tyres is close to each other. The oil yield of waste tyres is around 40% while waste rubber is around 35%. But the oil yield of waste plastic is relatively higher than waste rubber products. Pure PE plastic has the highest oil yield around 95% while pure PP plastic has an oil yield of around 90%.

When you plan to invest in a continuous pyrolysis plant, you should know which waste products are more suitable for the machine. Knowing the oil yield of different waste materials is important in this regard. The best thing is to invest in a continuous pyrolysis plant that can process waste materials with the highest oil yield. You will earn more money in the process.

The Working Process Of A Continuous Tyre Pyrolysis Plant

A continuous tyre pyrolysis plant works 24/7 with very little maintenance on your part. The waste materials should be smaller in size to keep the continuous feeding and discharge system operating 24/7. Make sure the waste tyres are shredded into smaller pieces before you feed them into the system. You can either invest in a specialized tyre shredder or do the work manually before feeding the waste tyres into the system. The continuous machine has a unique sealed feed system to feed the broken tyre blocks into the pyrolysis reactor for a sustainable feed process: https://bestonasia.com/pyrolysis-plant/continuous/.

What To Consider When Buying A Continuous Tyre Pyrolysis Plant?

There are many factors to consider when shopping for the best continuous tyre pyrolysis plant for sale. Here are some of the most important factors to consider:

- The reputation of the tyre pyrolysis plant manufacturers

- The capacity of the machine

- What raw materials to use

- The price of the machine

- On-going maintenance requirements

- The location of the machine

The aforementioned article provides information on what you need to know about a continuous tyre pyrolysis plant, and how to choose the right machine for your business.