In today’s rapidly evolving industrial landscape, the importance of embracing sustainable practices cannot be overstated. Amidst global concerns about climate change, resource depletion, and environmental degradation, industries are seeking innovative solutions that not only meet their operational needs but also contribute positively to the planet. One such avenue gaining traction is the utilization of biochar production equipment, which stands at the intersection of technology, sustainability, and environmental responsibility.

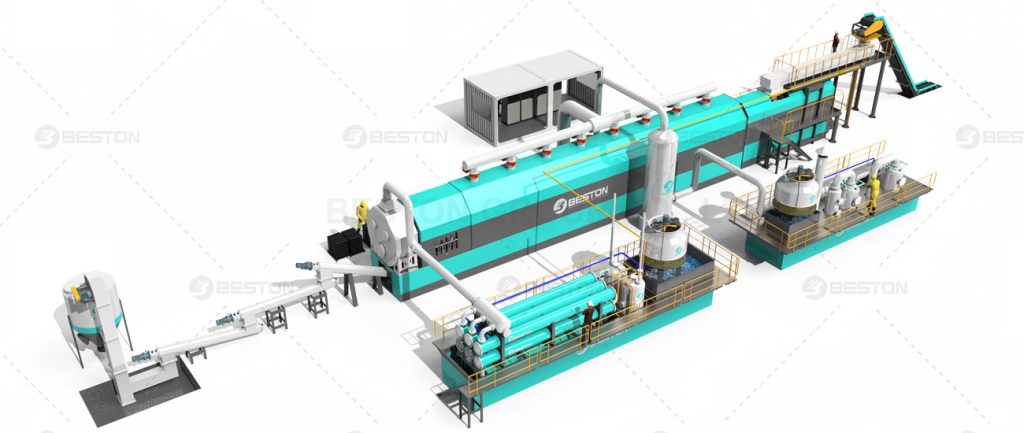

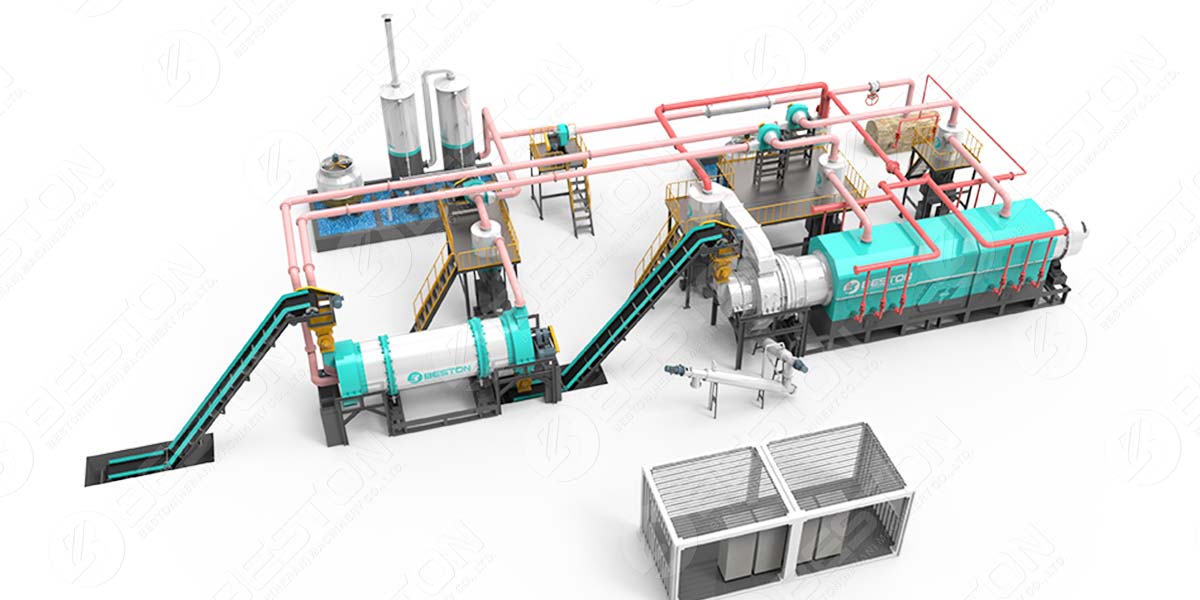

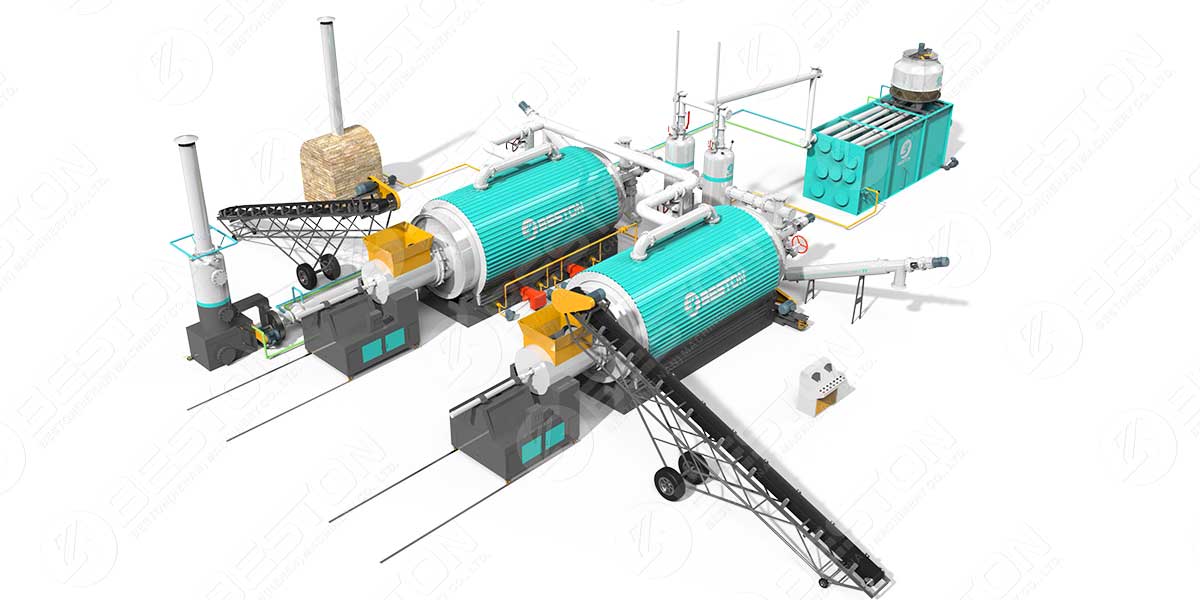

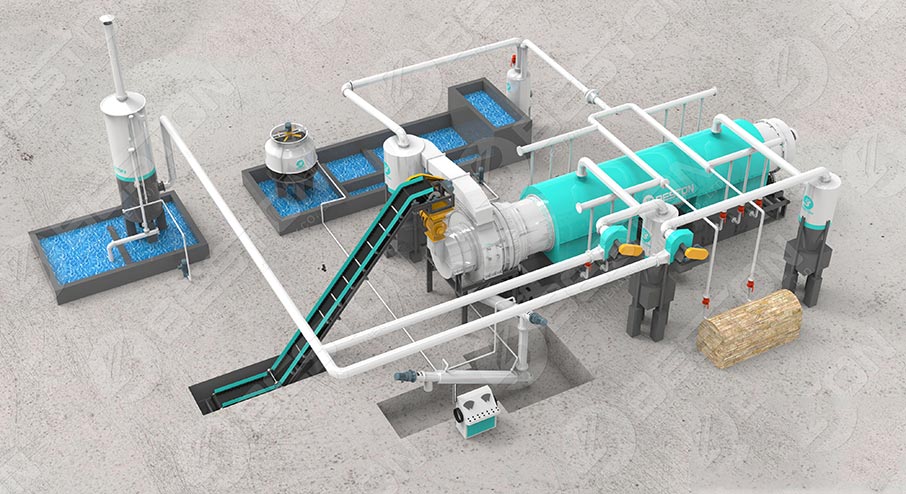

Beston Biochar Production Equipment for Sale

Understanding Biochar Production

Biochar, a highly porous carbonaceous material derived from the biomass pyrolysis plant, has emerged as a versatile tool in the pursuit of sustainability. Its significance lies in its potential to sequester carbon and improve soil quality, thereby contributing to carbon neutrality and enhanced agricultural productivity.

The biochar production process revolves around pyrolysis, a thermal decomposition process carried out in the absence of oxygen. This results in the breakdown of biomass into biochar, syngas, and bio-oil. Feedstock selection plays a pivotal role in determining the quality of biochar and its subsequent impact on the environment. Different feedstock types, such as wood chips, agricultural residues, and even algae, yield distinct biochar properties, influencing its suitability for diverse applications.

Biochar Production Equipment: Technological Advancements

Technological advancements have propelled the evolution of biochar production equipment, enhancing its efficiency and output. High-efficiency pyrolysis reactors with improved heat transfer mechanisms have enabled higher biochar yields while minimizing energy wastage. These reactors optimize temperature profiles and residence times, ensuring the optimal conversion of biomass into valuable biochar.

The integration of automation and control systems has streamlined the biochar production process, reducing human intervention and ensuring consistent product quality. These systems monitor and regulate temperature, gas flow, and other critical parameters, guaranteeing optimal pyrolysis conditions.

Furthermore, the design of biochar production equipment has become more sophisticated and versatile, accommodating different feedstock characteristics. From the shape and size of the reactor to the choice of heat sources, these tailored designs enhance overall efficiency and address the unique needs of various industries.

Environmental Benefits of Biochar Production Equipment

The environmental benefits of employing biochar production equipment are multifaceted and compelling. First and foremost, biochar plays a crucial role in carbon sequestration, effectively locking away carbon dioxide that would otherwise contribute to atmospheric greenhouse gas concentrations. By incorporating biochar into soils, not only is carbon sequestered but the material’s porous structure enhances soil water retention, nutrient availability, and microbial activity.

Moreover, the integration of biochar into agricultural practices has shown remarkable potential for soil enhancement. Its ability to improve soil structure, increase cation exchange capacity, and reduce nutrient leaching bolsters its role in sustainable agriculture. This, in turn, leads to increased crop yields and reduced reliance on synthetic fertilizers, thus promoting ecological balance.

Additionally, the use of biochar production equipment aids in the reduction of organic waste. Organic residues, such as crop residues and wood chips, can be transformed into valuable biochar through pyrolysis, preventing their accumulation in landfills and decreasing the generation of harmful emissions.

Economic Viability and Scalability

As industries increasingly recognize the economic and environmental benefits of biochar, the viability of investing in biochar production equipment becomes more apparent. The return on investment (ROI) in these systems is influenced by factors such as feedstock costs, biochar market demand, and potential revenue streams from carbon offset programs.

Deciding between small-scale and large-scale biochar making machines involves considerations of available resources, intended applications, and market dynamics. Small-scale systems are well-suited for localized waste management and niche agricultural applications, while large-scale systems have the potential to make substantial contributions to carbon sequestration and soil improvement on a broader scale.

Market trends indicate a growing demand for sustainable solutions, with industries ranging from agriculture to wastewater treatment recognizing the value of biochar. This trend is likely to spur innovation and competition in the biochar equipment industry, further driving down costs and expanding its accessibility.

Challenges and Future Prospects

While biochar production equipment offers substantial benefits, several challenges must be addressed to maximize its impact on sustainability. Energy consumption during pyrolysis remains a concern, as it can offset the environmental gains achieved through carbon sequestration. Innovations in energy-efficient pyrolysis technologies and renewable heat sources are crucial to mitigating this challenge.

To ensure the sustainable deployment of biochar production equipment, regulatory frameworks and standards need to be established. These guidelines should address emissions, product quality, and land use practices to prevent unintended negative consequences.

Looking ahead, the potential applications of biochar are extensive and diverse. From water purification to building materials, biochar’s versatility holds promise for various industries. Collaborative research and innovation will likely uncover novel applications, broadening its influence and enhancing overall sustainability. Beston Group is a manufacturer dedicated to producing more environmentally friendly biochar machines. If you want to get a solution, you can consider contacting us.

In conclusion, the evolution of biochar production equipment marks a significant stride toward enhancing sustainability in industries across the board. The seamless integration of technological advancements, environmental consciousness, and economic viability positions biochar as a compelling solution to mitigate climate change, enrich soil health, and pave the way for a greener future. As industries continue to embrace this innovative approach, the collective effort to create a more sustainable planet gains momentum.