Many leading companies are recording record profits through operating tyre to oil plants. Converting tyres to oil by pyrolysis can net your company very high amounts of profit if you correctly implement these processes into your current operations. However, when considering making an investment in these processes, you need to reduce costs as much as possible. Here’s how to reduce tyre to oil plant cost.

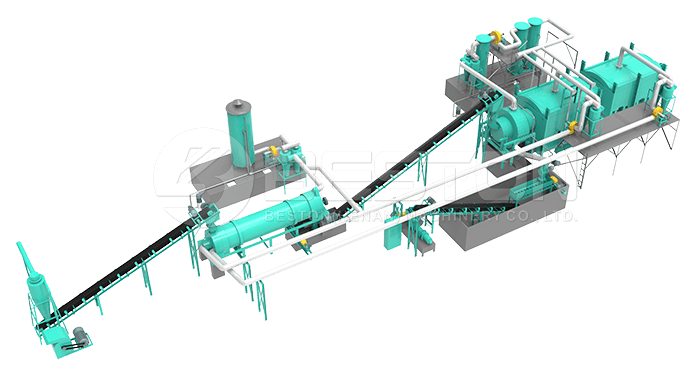

Tyre to Oil Plant in Brazil

The space requirements of tyre to oil plants play a large role in costs. Larger plants will cost you lots in terms of leasing out space to accommodate the plants. In some cases, the larger assets are worth the increased costs due to better output and efficiency. However, you cannot make assumptions about all of the large plants currently available. You should always consider the impact the size of a plant has on total business expenses when analyzing them for potential acquisition.

Tyre to oil plants also consume lots of energy, which is something you need to consider. If you cannot efficiently operate these plants, they will quickly eat up mammoth amounts of energy, leading to massive operating expenses. Luckily, Beston pyrolysis plant can make use of combustible gas produced during pyrolysis process. When tyre to oil processes are correctly implemented, the high energy expenses associated with the plants are offset by incredibly high revenues. You should always keep in mind the high energy requirements these plants have when analyzing possible investments.

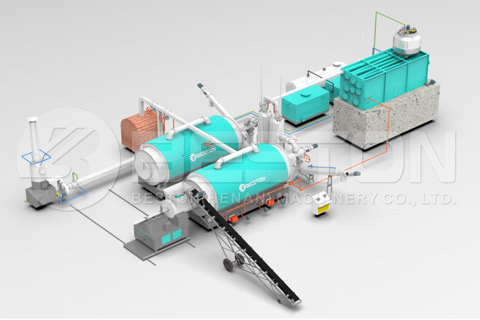

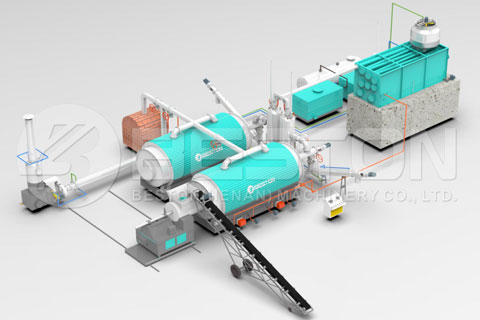

Tyre Pyrolysis Oil Plant in Jordan

Depending on the manufacturer, the price you can expect to pay for tyre to oil plants will vary dramatically. The average price of these plants is constantly fluctuating, which is why you always have to reference the most up to date industry figures when trying to ascertain what is a fair price for these plants. You should also consult with as many different manufacturers as possible to see whether or not you can get these plants for a lower price than the market average.

The easiest way to reduce tyre to oil plant costs is to negotiate with manufacturers and suppliers. These plants are in high demand at the moment, which has caused lots of suppliers and manufacturers to ramp up the production of these assets. It’s likely that some of these businesses may have overproduced these plants, which means they are in need of buyers. Some of these companies will likely reduce their price dramatically should you negotiate with them. But we still advise that do not rely on the price only. Here are some tips for you: https://ecobeston.com/how-to-select-pyrolysis-plant-suppliers/.

You should look into tyre to oil plant manufacturers and producers that have strong connections with industry associations. Respected businesses that work in the pyrolysis industry often have the best deals when it comes to the plants that they produce or sell. These companies usually have lots of industry connections, which allows them to offer the lowest prices on these plants while still retaining high profit margins. You should research pyrolysis industry groups, such as Beston Machinery, to see whether or not you can find members willing to sell you tyre to oil plants.

One guaranteed way to reduce your costs when investing in tyre to oil plants is to go with old plants for sale. Although going with an old plant will decrease the required capital for an initial investment, they likely won’t deliver your company a good return. In general, it’s better to pay more for newer and more efficient plants.