Our modern world depends on booming haulage and transportation to keep modern societies mobile and supplied with their every need. Tyres are being used to their last surviving tread. Worse more, many landfills in environmentally conscious nations will no longer accept tyres in landfills and waste dumps as they are not a “disposable” item. Fortunately, tyre pyrolysis plant is able to turn waste into something useful. And pyrolysis plant manufacturers in China will be a great choice for investors.

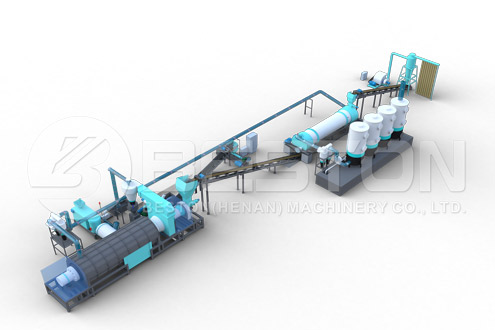

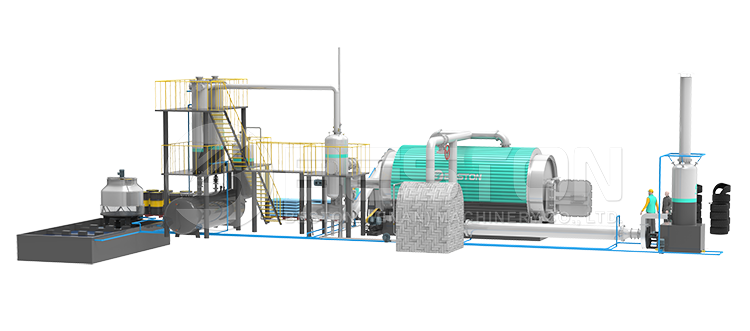

Pyrolysis Plant Design

Believe it or not, no matter how threadbare your tyres may seem there is still plenty of good in them if you have the equipment and know-how to access the valuable sequestered in your average tyre. Following is an overview of one such solution.

Advantages of Pyrolysis Plant in China

Millions and millions tyres are being discarded every day across the world and it was only a matter of time toil someone figured that this abundant waste also represents and considerably valuable sustainable resource.

On one hand, waste tyres cause a problem as they can lie around littering vacant lots and form a perfect breeding ground for disease carrying mosquitos. But with the application of the proper equipment, these tyres can be put to good use once more.

Tyre pyrolysis plant manufacturers in China have produced a suitable solution that involves transforming these wasted tyres into oil and other products that are useful and profitable. That’s why waste tire pyrolysis plant is also known as tire to oil plant. The term “pyrolysis” actually means to be transformed through fire and describes the chemical transformation of things burned in low-oxygen conditions.

Tire Pyrolysis Machine to South Africa

You probably there is more in a tyre than you will find in your average rubber ball. Actually, almost 40% of the tyre consists of materials that can be salvaged and repurposed.

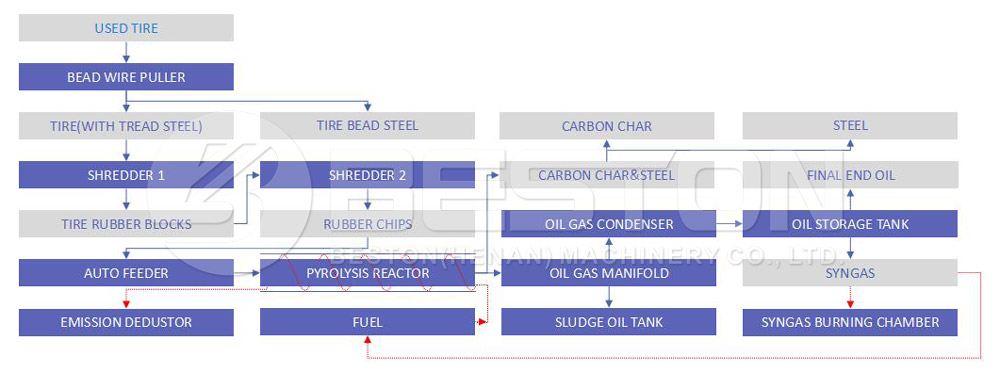

Tyre Pyrolysis Process

A tyre pyrolysis plant crafted by reputable manufacturers in China features an advanced design. Inside the tyres and their constituents will be subject to high temperatures and will be transformed into marketable products, such as pyrolysis oil, carbon black and steel wires.

The evaporated constituents of the tyres for example can be collected in a condensing chamber and transformed into an oily substance called “syngas”, which has applications in the fuel industry. Furthermore, steel is another ingredient in most tyres and can be extracted and returned to the scrap metal industry.

Final Notes on Tyre Pyrolysis

While the tyres we use for travel and transport can cause a considerable waste management issue, there are alternatives to those with a mind for business. A pyrolysis plant allows the entrepreneur to close the link between waste tyres and new profitable products. Beston Group in China has quality waste recycling plant for sale, including pyrolysis machine, waste sorting machine and charcoal making machine. Welcome to contact them for details!