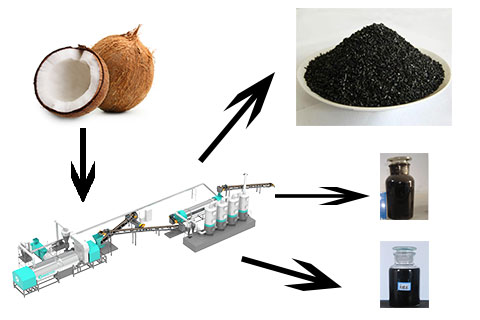

The bamboo charcoal machine takes waste bamboo and transforms it into charcoal. This machine is easy to use and it is very effective. It works fast to take any kind of waste bamboo and transform it into something that is easy to use and sell. This machine is very effective and it makes a lot of charcoal quickly.

You won’t have to worry about the effect of the machine on the environment either. This machine is very environmentally friendly and it is equipped with special equipment that ensures that no pollution escapes the machine. You don’t have to worry about the effect of this machine on the environment and it is going to work hard to keep the money rolling in. This bamboo charcoal machine is very easy to set up and the operating costs are low.

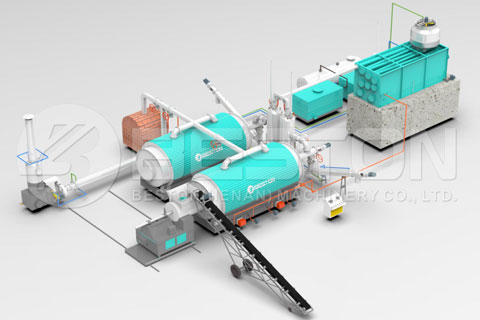

Beston Bamboo Charcoal Machine

You don’t want to end up working with a machine with high operating costs which makes this machine a great bargain since the costs are so low. You can easily get it up and running. The charcoal machine is made with the best parts which ensure that the machine is going to work hard for you and won’t cause problems. You won’t have to worry about the machine breaking down and it is going to keep you satisfied (also can be used as sewage sludge treatment plant).

The charcoal is high quality and you can sell the charcoal or use it in other ways. The charcoal will help you take care of all of your needs and it increases your business productivity. You can make money fast with this biochar making machine since it produces so much charcoal. The charcoal is easy to sell and there are lots of things you can do with it that will make you money.

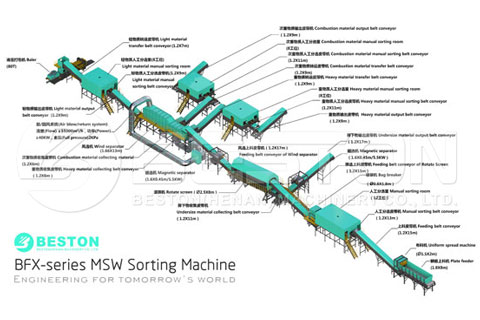

Biochar Machine for Sale

When you need to make money and you want to get a lot done you should make sure that you invest in this machine. The machine is a great investment in your business and it will help you make a lot of money. You need to make as much money as you can when you are in business and it will be much easier to make more money when you choose a good charcoal machine.

The machine comes in a variety of sizes and it will be easy to choose the size that is going to be the best deal for your needs. You can quickly find a machine that is going to work for you. The manufacturer is even going to help you choose the right machine.