Are you wondering about the fully automatic egg tray machine price? If so, you have come to the right place. A full automated egg tray machine comes with many benefits for your business. It is very easy to operate and save labor costs. There are egg tray machines with different capacities to make between 1,000 to 6,000 pieces of egg trays an hour. There are many factors that affect the price of an egg tray machine. This article provides information on what you need to know when buying an egg tray making machine.

BTF-1-4 Egg Tray Machine to Colombia

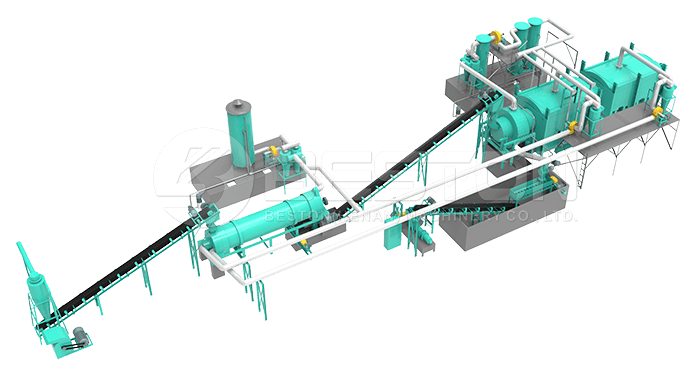

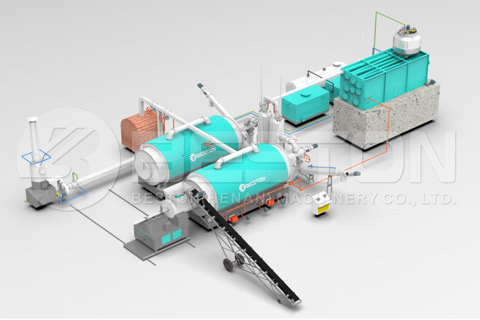

Easy operation is one of the most important benefits of an automated egg tray making machine. The machine will do most of the work to make your egg trays due to the high level of automation. The fully automated machine has an automated drying & packing system too. You need only a few employees to operate the entire production line. In fact, you will save thousands of dollars on labor costs with such a machine. The drying feature that comes with the automated egg tray machine will let you dry the egg trays even if it is raining outside. It uses a metal dryer machine, which can also save your space. If you invested in a manual egg tray making machine to save a few bucks in the process, you can’t dry the cartons in the sun when it is raining outside. The automated machine is much quicker than drying the cartons in the sun. But it is low-cost. If you are new to this business or have a limited budget, you can have a manual egg tray machine. Moreover, the latest fully automated egg tray machines are designed to recycle the heat inside to lower your fuel costs.

Automatic Egg Tray Machine to Russia

You don’t need a large labor force, as well as the necessary space, to dry egg trays when you buy an automated egg tray machine on the market. The metal dryer that comes with an automated machine is multilevel in order to save floor space. If you want to improve the efficiency and productivity of your work and have limited space, you should definitely invest in an egg tray machine. The price of an egg tray machine may vary depending on many factors such as the production capacity, working methods, etc.

The average price of an egg tray machine is between $10,000 to $70,000. Most of us believe that the egg tray making machine price in India will be lower. It may be. But we suggest that do not rely on the egg tray machine price only. The quality of the machine, reputation of the manufacturer, warranty offered, the capacity of egg trays per hour, and many other factors can affect the price of the product. You should invest in the right product depending on the capacity of trays you plan to produce per hour and your budget.

If you are looking for an egg tray making machine, you have come to the right place. The aforementioned article provides information on what you need to know when buying an egg tray making machine. If you want to get a customized paper egg tray manufacturing project report, please check the link here: https://bestoneggtraymachine.com/egg-tray-manufacturing-business-plan/.