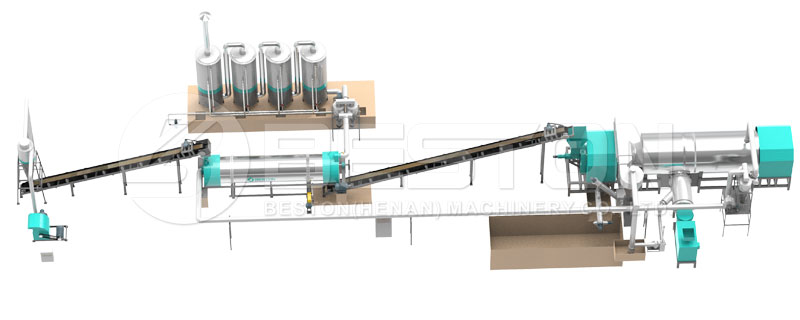

Bamboo charcoal has been around for centuries, but the carbonization process used to create this has changed over the years. Today, there are carbonization machines designed to complete this process without any issues. The charcoal making process itself has four stages that the bamboo works through to produce charcoal.

The Drying Stage

The first stage of this process is the drying stage. As the name suggests, the bamboo is dried and as much moisture as possible is removed. To achieve this, the bamboo is placed in a kiln that does not reach more than 120 degrees Celsius. This removes the water in the bamboo while leaving the chemical composition alone.

The Pre-Carbonization Stage

Once the bamboo is dried, it moves onto the second stage of the process which is the pre-carbonization stage. The bamboo will remain in the kiln, but the temperature is increased to up to 260°C. When this happens, there is a chemical reaction in the dried bamboo. Click https://www.bestongroup.com/biochar-production-equipment/ for more.

At this heat, the chemicals become unstable and start to decompose. They will release a mixture of carbon dioxide and carbon monoxide as this happens. It is vital that this stage occurs where there is proper ventilation to take care of these gasses.

The Carbonization Stage

After the chemicals start to break down, the bamboo moves to the third stage of the process. At this point, the temperature in the kiln is increased further to around 450°C. The bamboo will start to break down and release gasses and liquid products.

The gas products will include flammable ethylene and methane. The carbon dioxide produced by the process will decrease when it reaches this stage. The liquid products include methanol, bamboo tar, and acetic acid. These products can be harvested for other uses if the bamboo charcoal making machine allows for that.

The Refining Stage

The last stage of the carbonization process is also when the kiln becomes the hottest. During the stage, the temperature will exceed 450°C and the remaining bamboo material will turn into charcoal. Once the material starts turning into charcoal, it will be separated into three categories of low, middle and high-temperature charcoal.

After the charcoal has been created, it will move to the last part of the process and the end of this stage. This is when the charcoal is allowed to cool down. This process can take between 5 to 8 days depending on the environment the charcoal is placed in and the volume produced. During this phase, liquid can be extracted such as tar, vinegar, and alcohol. These products will have various uses, but will generally need to go through their own refinement process to create the final products.