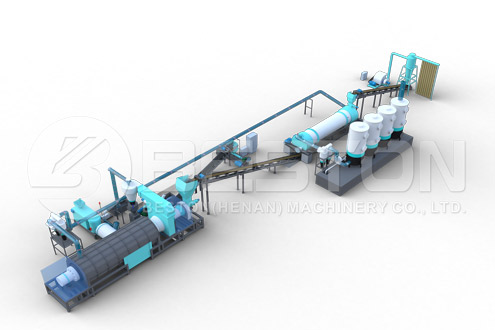

The waste treatment plant has a streamlined design that is attractive and also very efficient. The machine is designed to move the trash through as efficiently as possible and you can process tons of trash with this machine.

The waste treatment plant (planta tratamiento residuos) separates garbage into piles so it can be used for recycling and also used to create new things. The plant is very efficient and it can be used to process many types of waste.

Design Of Waste Treatment Plant

The plant has a 95 percent accuracy rate which means that you can process the trash quickly and you won’t need to hire as many people to work on the machine. You will need people to help sort the trash in the beginning because you can’t have large pieces of trash go onto the machine. It is very important that you go through the trash on the conveyor belt and pull out any large items like tree branches, furniture, or other large items.

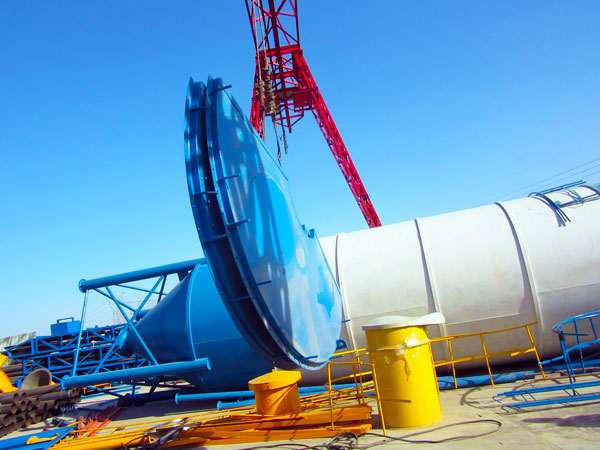

The plant is very safe and it is fully sealed. Your workers will not be exposed to bad odors or smoke. The machine stays cool and it doesn’t emit air pollution which makes it easy on the environment.

There won’t be any residue left after the sorting process is done which means that you don’t have to worry about putting any trash into the landfills. The plant can handle a lot of trash and the working environment is going to be comfortable when you are working with this plant. The plant is going to make it easy to get things done and you won’t have to deal with a lot of issues when you use one of these plants.

Trash sorting machine

The plant is very safe and you can easily process a lot of trash with this machine. When you are looking for a trash machine that is efficient, look for the machine that has the best design. The plant is affordable and it can help you take care of all of your trash processing needs.

This plant (segregacion de basura) is very safe and you can process a wide variety of trash with it. The machine can be used to process food, agricultural, and living waste as well. There are four different models to choose from and you need to make sure that you choose the model that is going to work best for your needs.

You don’t have to make a big investment in this machine and it provides you with an affordable way to process trash. The machine is very efficient and it has a low failure rate. The heat and gas that the machine produces is recycled which means you don’t have to spend as much money on running the machine.